How to order

You can order direct from us or go through a brick factor.

The most important thing to remember is that handmade bricks can’t be hurried. Whilst we may carry stock of the brick you want it is wise to start talking to us three to five months before you need your bricks.

Request a sample

Screens don’t always present colours accurately so there is no substitute for seeing your proposed brick in real life. You can use this button to order the samples you are considering.

People

Nowadays, WH Collier is run by a dedicated team, each of whom is crucial to the production process and shares a deep commitment to the heritage and distinctive qualities of our bricks. It is led by Nikki Lax and Mark Strugnell.

Nikki Lax

I am responsible for sales, finance and administration so I am generally the first point of contact for all new enquiries. I also have overall responsibility for Health & Safety and Environmental Management. I am also our designated Quarry Manager and plan and manage our clay digs.

I started work at WH Collier in 2013, but actually, I have known it all my life. My father Maurice, was the Kiln Manager and eventually a Director of the company so, growing-up, the brickworks was my playground. In fact my Grandfather also worked in the brick industry so it runs in the blood.

I initially started doing holiday cover in the office and then took on more responsibility. I became a Director and co-owner in 2016.

I particularly love how we take a natural material, formed over hundreds of thousands of years, and transform it into product that is used to make buildings which that will themselves, last hundreds of years.

When I am not at work I am generally to be found in the fields with our horses and supporting my son at riding competitions.

Mark Strugnell

I started here as a Brick Maker back in 1993 and have since done every job on the production side of our business from mixing the sand and stains to setting the kiln. In that time we have reduced from about 25 to 8 people with a shift of emphasis from quantity to quality.

I have overall responsibility for production with particular focus on quality control at every stage of production.

In 2016 I became a Director and of the company.

For me, it is the hand-made character of our bricks compared to machine-made that keeps me coming in every day. I love it when we get asked to make a special. Liaising with the customer, working with our Mouldmaker, going through the process of testing and producing a new shape and that big moment when they come out of the kiln. We have been doing it long enough now to know what to expect but it still feels like magic.

In my free time, I operate a taxi service for my two daughters who seem to need running everywhere and anywhere. I am deeply committed to seeing them grow up well.

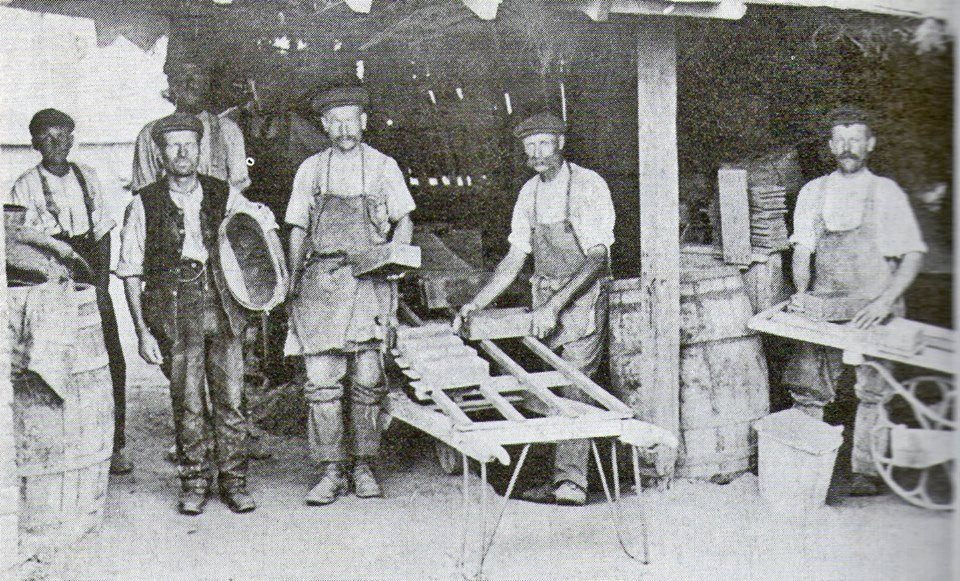

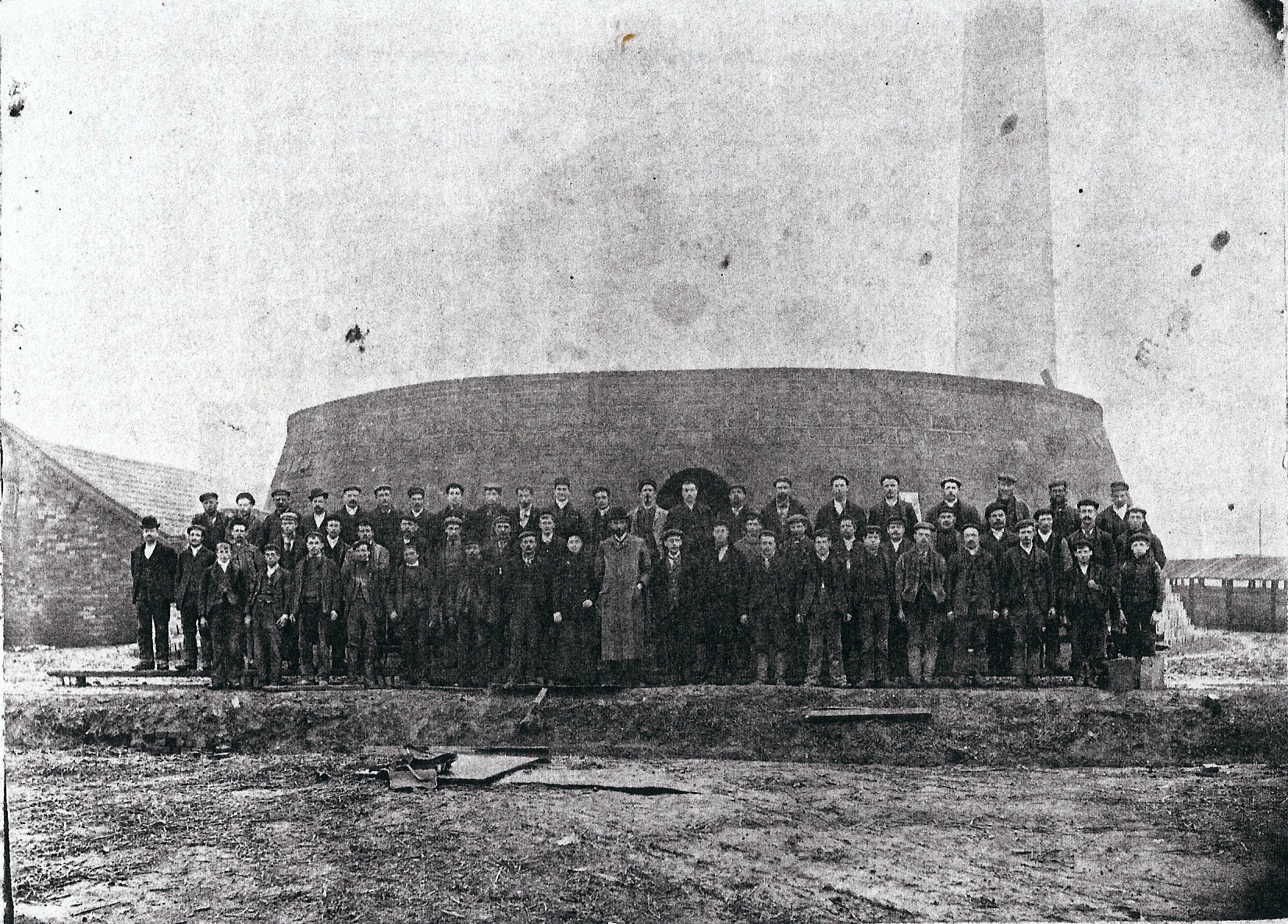

160 years of brickmaking

Brickmaking began in 1863 when William Homan Collier came to the area from the E & R Collier brickmaking business in Reading.

A pair of downdraft kilns built around 1880 still survive and are now listed on The Industrial Register.

At its busiest, production was over 5 million pieces per year. The product range included bricks, flower pots, land drain pipes, roofing tiles and fireplace briquettes.

The company remained part of the Collier family until 1988 when it was acquired by Salvesen Brick which became Chelwood Brick and then, following a merger with Ambion Brick, The Brick Business.

In 2004, The Brick Business was bought by Weinberger who decided to close the company. Recognising the unique value of W H Collier, the business was bought by the then General Manager Maurice Page and four of his team.

The product range was improved with the addition of the Primrose Range, a through colour Yellow.

In 2020 the Primrose range was extended with the addition of Primula Yellow.

There is currently a team of 8 working at the site, continuing the tradition of handmade brick making.